EI-LOALOAA MARINE FO DIVING & PETROLEUM SERVICES

Commercial Diving

Marine Contractor

World-class Global Shipping Husbandry

Owner

EL-LOAOAA MARINE for Diving and Petroleum Services:

A Legacy of Over 40 Years of Expertise

EL-LOAOAA MARINE For Diving and Petroleum Services boasts a rich heritage of over 40 years in the underwater exploration and petroleum support industry. Our extensive experience enables us to navigate complex challenges with unparalleled proficiency, ensuring the highest standards of safety and efficiency. Our seasoned professionals apply decades of knowledge to deliver innovative solutions tailored to the oil and gas sector. With a proven track record of success, we are committed to excellence in every project, making us the trusted choice for all your underwater needs.

Best Regards

Captain / Bahaa El-Din Radwan

Our Clients

Why Work With Us

Why people are very loved to working with us?

Underwater Hull And Propeller Cleaning

The maintenance of the hull and propellers is indispensable for vessels in operation, as it turns out to be the most economical solution reducing the drag, weight and excessive fuel costs. Hull cleaning of vessels is carried out either along designated terminal quays as well as the anchorage with Brush Kart systems. Machines capable of cleaning up to 800m2/hr adopt specific brushes to clean any kind of growth whilst protecting paint coatings. Additional cleaning applications also include using HP water jetting up to 500 bar.

Propeller polishing is carried out using high-speed hydraulic machines which are specifically designed for a multi-stage cleaning and polishing process comprises the blades, roots, boss, and cone up to Rupert Scale grade ‘A’.

- Carried out in Outer Territorial Water (OTW)

- mprove Performance

- Save on Fuel Costs

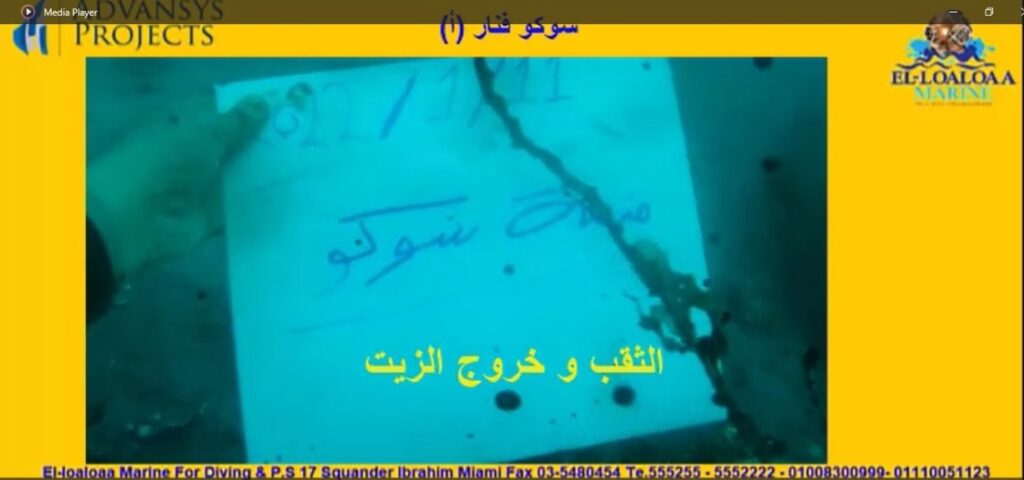

Maintenance and inspection of marine petroleum particles

- Inspection of steel thickness of offshore platforms

- Inspection of efficiency and change of cathodic protection

- Inspection of cracks

- Inspection of the efficiency of marine pipes

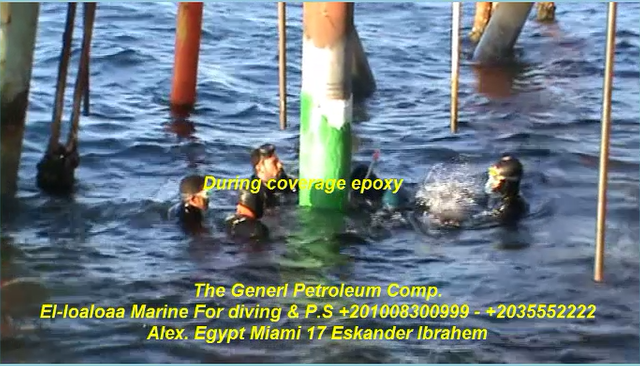

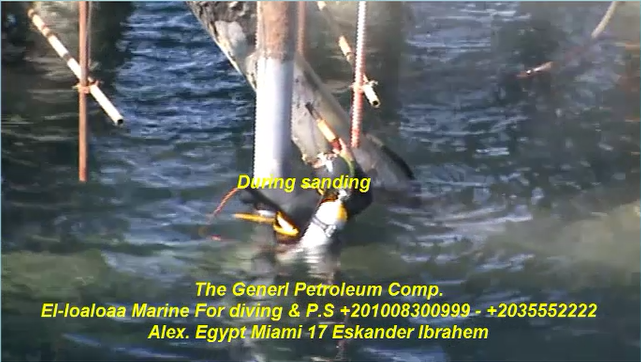

- Sanding the splash zone areas of platform's and covering them with epoxy

- Laying and maintaining submarine cables

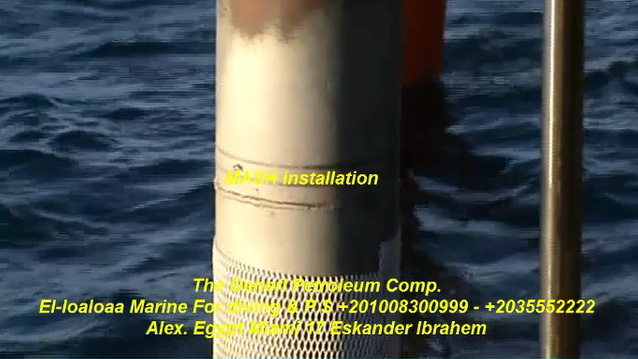

Maintenance of Splash Zoe area of offshore platforms

- Inspection of steel thickness of offshore platforms

- Inspection of efficiency and change of cathodic protection

- Inspection of cracks

- Inspection of the efficiency of marine pipes

- Sanding the splash zone areas of platform's and covering them with epoxy

- Laying and maintaining submarine cables

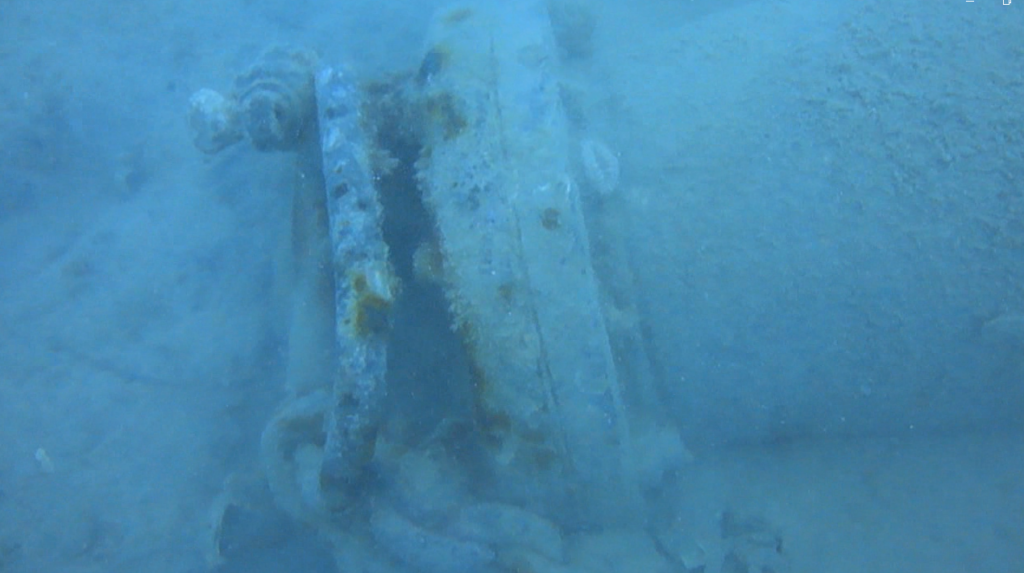

In-Water Surveys And Inspections

Operations are carried out using digital CCTV photographic/ video equipment and supported by detailed technical reports with job descriptions.

- UWILDS

- Class Extensions

- Fouling Conditions

- Pre-purchase

- Routine hull programmes

- Non Destructive Testing (NDT)

Underwater Repairs And Maintenance

Our esteemed service offers a rapid-response team comprising certified, CLASS APPROVED welders. We excel in providing a diverse array of underwater maintenance and repair solutions, meticulously tailored to meet the specific needs of various applications worldwide. Trust us to deliver unparalleled expertise and efficiency, ensuring seamless operations regardless of location

- Propeller Repairs

- Shell Plating Repairs

Offshore

Operating worldwide and with containerised systems, Triton offers various services relating to the oil and gas sectors.

- Underwater surveys & inspections including N.D.T

- Underwater high pressure jet cleaning

- Underwater cutting and welding

- Habitat and cofferdam operations

Internal Maintenance & Repairs

Custom fabrication work on both emergency and scheduled projects comes down to experience and years of working with all materials and specifications

- Valve repair and replacement

- ICCP installation and replacement

- Sea-chest grids replacement

- Impress cathodic protection replacement

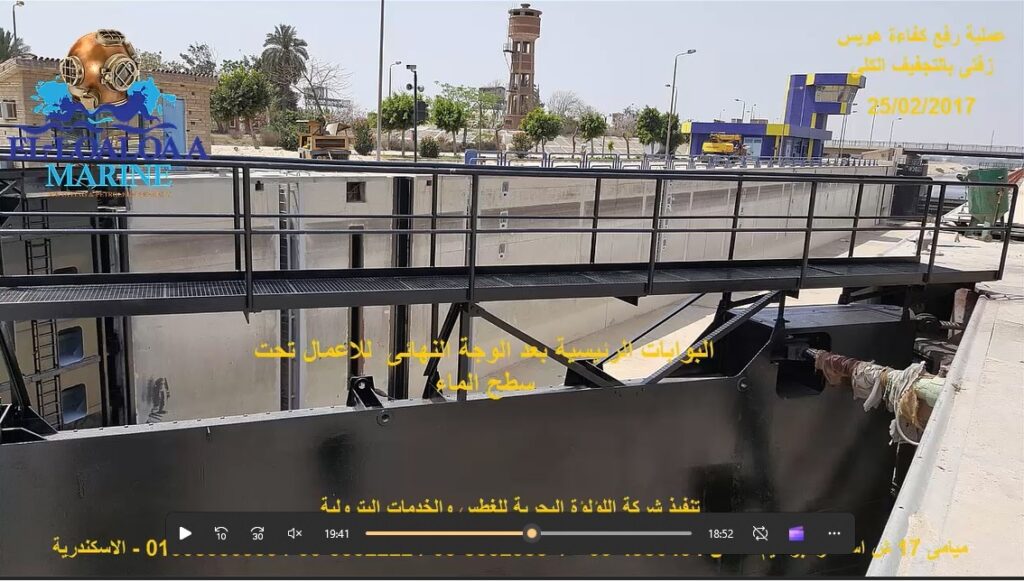

General petroleum com.Pipeline flashing

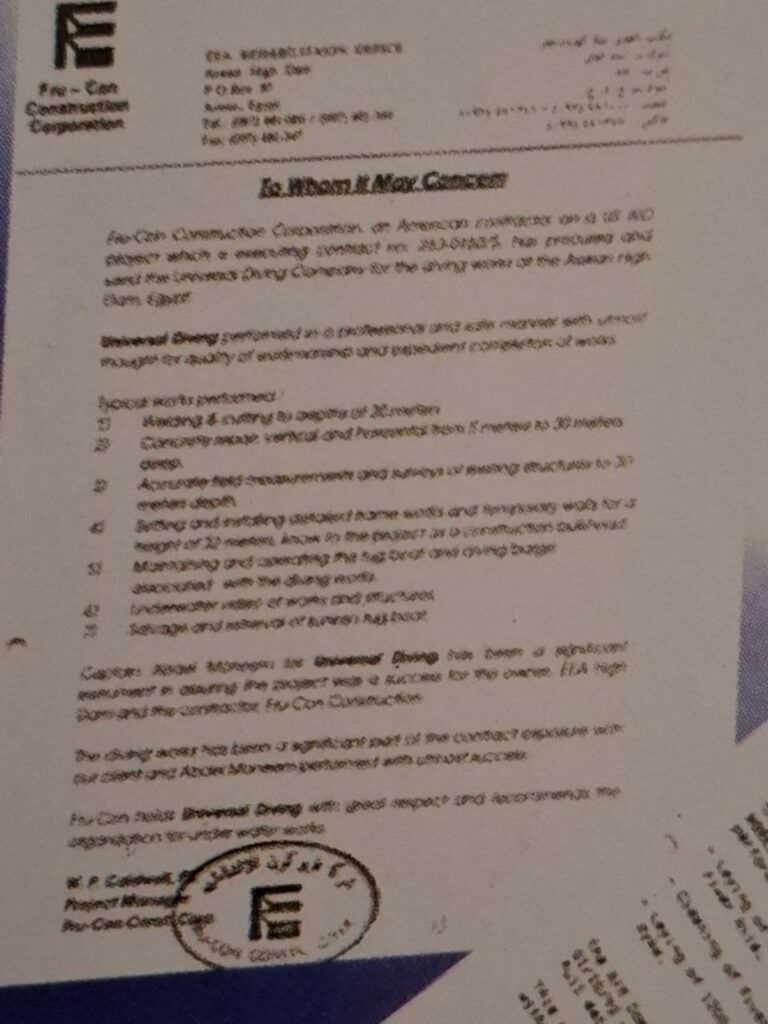

Zefta Project

Maintenance and rehabilitation of the Zefta lock for maritime navigation by complete drying

- Install alternative gates at the entrance and exit of the lock

- Dry the lock completely

- Maintenance and rehabilitation of all under water steel stricture

- Sand pulsating paint from the main gates and all the steel surface and repainting.

- Painting all submerged steel stricture

- Maintaining and painting gates and changing water leakage rubber

- Maintenance and renewal of the communication and electricity network in the control and operation tower

- Maintenance and rehabilitation of the mobile bridge on the lock road

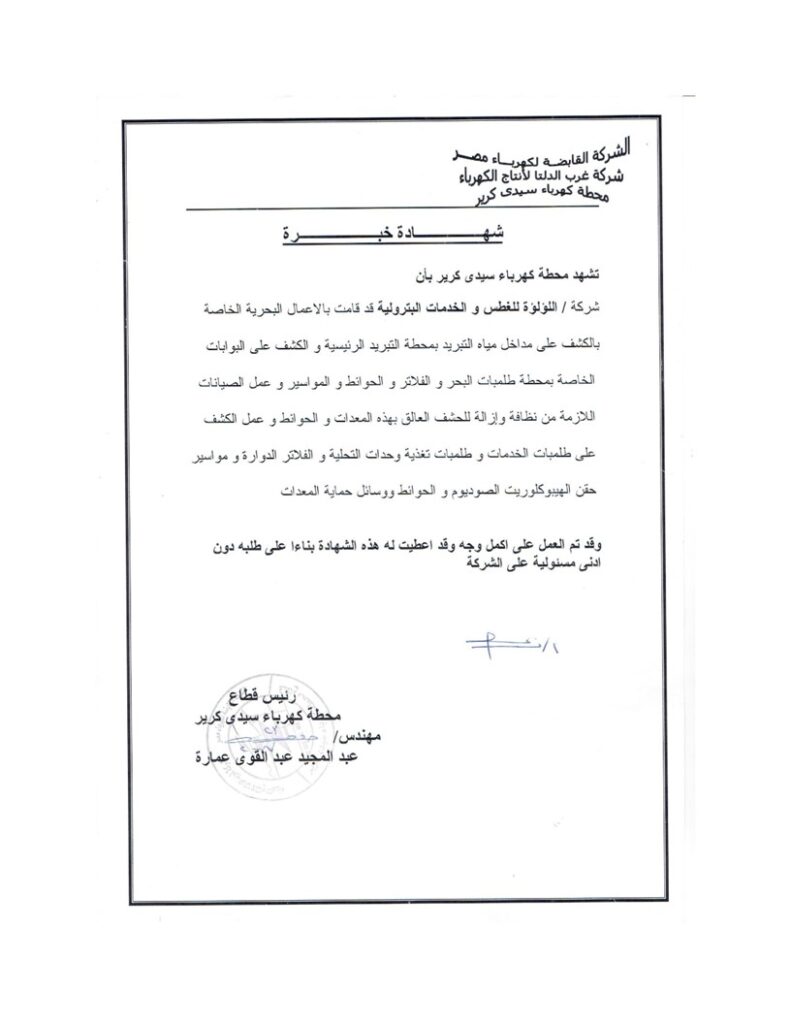

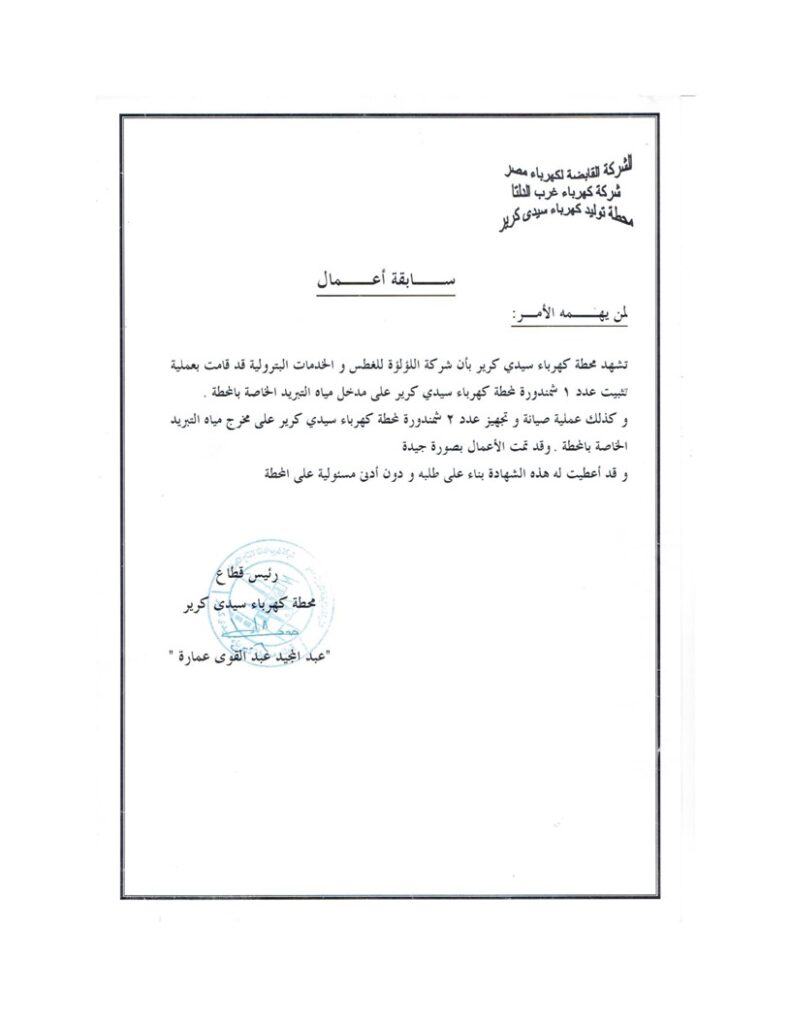

Rehabilitation and Maintenance of Power Generation Stations

1. Inspection and photography of cooling water inlet and outlet areas.

2. Preparing necessary reports for maintenance work.

3. Inspection of concrete walls and basins.

4. Inspection of submerged steel parts under water.

5. Inspection and maintenance of weed and debris prevention nets.

6. Inspection and maintenance of cathodic protection systems.

7. Removal and cleaning of water cooling inlets from marine growth and sea debris.

8. Cleaning and removal of marine growth and sediment from settling basins.

9. Inspection and maintenance of cooling water intake pipelines.

10. Maintenance and repair of all submerged concrete structures and areas exposed to wave

CERTIFICATION AND CLASS

Approved By Major Classification Societies